Non-destructive testing (NDT) method such as computer tomography (CT) are more and more used as imaging techniques to analyze the inner structure and to detect flaws in concrete specimen. In this project algorithms have been developed to find cracks automatically in CT images of concrete. The goal is to quantify damage processes in cementious material in space and time. Three different crack detection methods have been evaluated. The statistical evaluation of detected cracks and the tracking of single cracks over several frost-thaw cycles are future project goals.

INTRODUCTION

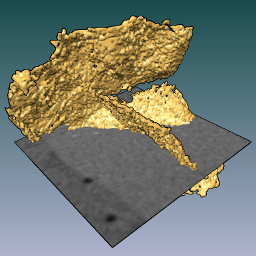

Analyzing damages at concrete structures due to physical, chemical and mechanical exposures need the application of innovative non-destructive testing (NDT) methods to trace spatial changes of microstructures. The images are obtained by 3D computer tomography with a very high resolution. This leads to data sets of more than 6 GB per concrete specimen.

GOALS

- Development of algorithms to find cracks automatically in noisy CT images of concrete

- Quantification of damage processes in cementitious material in space and time

CRACK DETECTION METHODS

Three different crack detection methods for the analysis of computed tomograms of various cementitious building materials have been evaluated.

Known Methods:

The following methods have been evaluated:

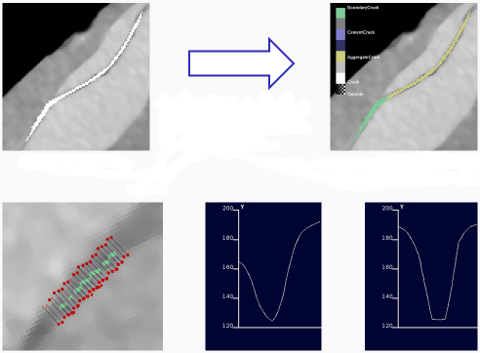

- Template Matching, which finds points where the image I is similar to a template T representing a crack

- Filtered Hessian Eigenvalues, where the eigenvalues of the Hessian matrix for every voxel are filtered to find sheet-like structures

- Percolation, an originally 2D algorithm based on the physical model of liquid permeation has been extended to 3D, while the 2D circularity test to check the resulting region couldn’t be adopted to 3D easily

New Method: Hessian-driven Percolation

- Result of the sheet-filter computed from the Hessian eigenvalues is used to extend the percolation algorithm to 3D

- Shape of percolated regions is checked by the coincidence with the result of the sheet filter (instead by the circularity as in the 2D case)

- Speed is improved by starting the percolation process only at points detected by the sheet filter

RESULTS

CONCLUSION

- Hessian-driven percolation may serve as a reliable crack detection method for bending and branching cracks if computation speed is the main criterion

- Template matching achieves the better results if accuracy and further crack investigations are the main goal

This is in contrast to previously given statements, but new results obtained from new datasets and computations convinced us tho change our opinion.

INVESTIGATIONS ON DETECTED CRACKS

To assess the concrete quality not only the number and size of cracks is important but also the material the cracks run through. This is called the embedding of the cracks. The images below sketch how this is done by evaluating the crack profiles.

FURTHER WORK

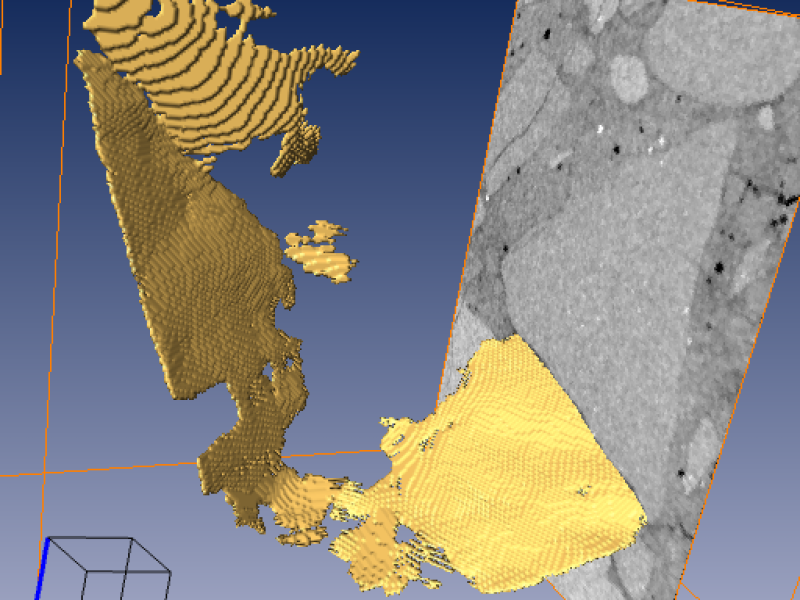

- Tracing of single cracks over time

- Using the result of the crack detection for further analysis, e.g. crack width or crack orientation

- Representation of cracks as point clouds and polygonal structures