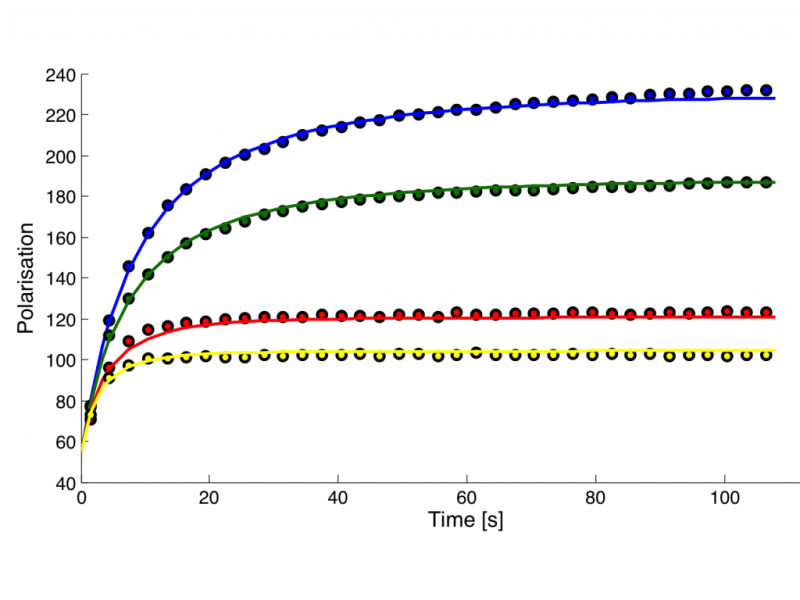

The company aokin produces and sells automatic analytic devices for the quantification of toxins in food. At present, the calibration of these devices is costly and time-consuming, thus economically not justifiable. The goal of the project presented here is to develop a model-based, computer-aided automatic calibration routine. This not only reduces the measurement effort, but also allows for the control of measurement errors. Measurement curves are generated by kinetic fluorescence-polarisation and are evaluated by error-oriented Gauss-Newton algorithms which compare the measurement data to well-defined reaction kinetic models. This allows for the determination of kinetic rate constants and unknown toxin concentrations. The method is applied to both single toxins, as well as to mixtures of multiple toxins, where concentrations can solely be determined in a model-based way. A quantitative rapid test for multiple toxins is not yet available on the market and fills an important gap in the quality management of food.