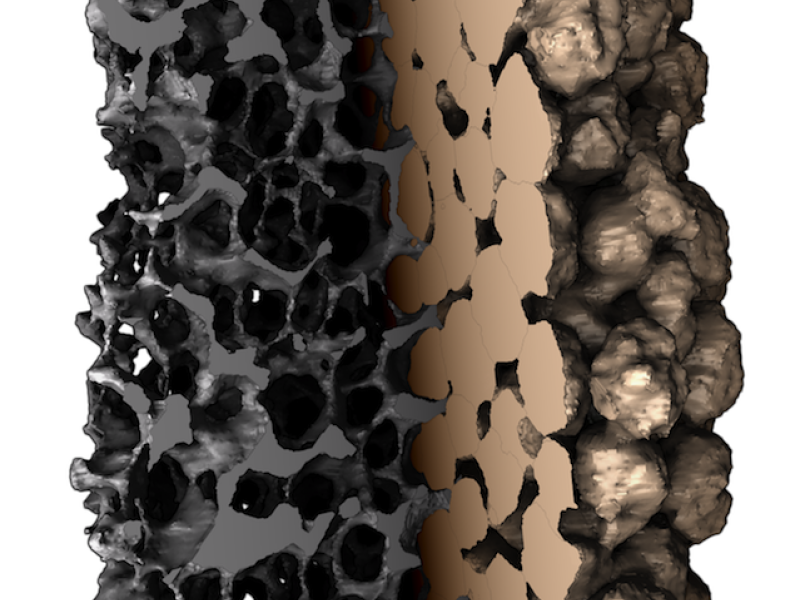

In the field of Bioengineering, additive manufacturing processes such as 3D printing is an emerging technology to investigate the production of tissues or organs. A long-term vision is to design and manufacture bone scaffolds using biodegradable materials for bone replacement and regeneration. Challenges arise from the material used for manufacturing and the mechanical properties of the printing system. These conditions determine the printable resolution for producing the scaffolds. This project is concerned with the analysis of natural spongy structures from micro-CT data and the generation of models for the printing process. We develop methods and software tools to extract and quantify structures such as struts and pores. Furthermore, the developed methods and implemented tools allow modifying and reconstructing the extracted structures in order to optimize the models with respect to the printing conditions.