Timetables dictate the daily operations of railways. Creating a railway timetable does not only involve determining arrival and departure times at stations, but also the following aspects:

- assigning trains to tracks in a detailed level and in high precision,

- resolving crossing and overtaking conflicts,

- respecting infrastructure capacities,

- guaranteeing safety standards,

- providing delay resistance.

Together with our partner Digitale Schiene Deutschland, an initiative of Deutsche Bahn AG, the project Microscopic Timetable Optimization aims for an automated computation of timetables meeting all these requirements.

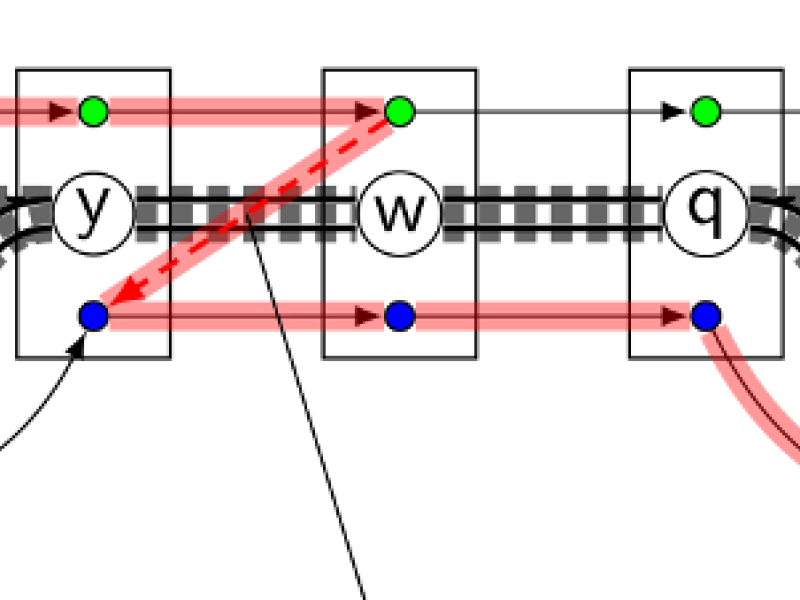

The main innovation in our model is the inclusion of ETCS Level 3/moving block, a novel signaling system, where trains operate under continuous supervision, and the headway between two trains can be reduced to the minimum braking distance. This allows a significant increase of track capacities, leading to more trains being offered and to more robust timetables.

The models and algorithms are tested on a real-world scenario comprising the corridor Hanover-Seelze-Wunstorf-Minden/Nienburg. This railway line is one of the most overloaded in germany and is part of the two Trans-European Network (TEN) corridors North Sea - Baltic and Orient/East-Mediterranean, passed by

- long-distance trains: e.g., Berlin-Cologne, Berlin-Düsseldorf, Berlin-Amsterdam, Bremen-Munich, Dresden-Cologne, Hamburg-Basel, Hamburg-Munich

- regional trains: e.g., from Hanover to Bielefeld, Bremen, Hamburg, Rheine

- local trains: S-Bahn Hanover

- freight trains starting and ending at Seelze, with more than 3,000 cars being shunted per day

On this corridor, we seek for a mathematically optimized microscopic timetable increasing the number of trains.