The goal of this project is to detect and quantify corrosion products in 3D-CT time-dependent images of steel-reinforced concrete specimens. The specimens are subject to artificial damage by applying an electrolyte solution together with a coupled electrical voltage. Several CT images are taken during this process while the first image is taken as the undamaged reference sample. The increasing volume of corrosion products in the specimens is then detected with image processing methods. The results can be statistically evaluated to depict e.g. the decreasing cross section of the rebar.

Introduction

In civil engineering practice the corrosion of the steel reinforcements inside concrete is a serious challenge. The ongoing process of corrosion reduces the diameter of rebars which has high impact on the stability of buildings. Furthermore corrosion products induce the formation of cracks which in turn leads to more corrosion. The goal of this project is to detect and quantify corrosion products in 3D-CT time-dependent images of steel-reinforced concrete specimens. The specimens are subject to artificial damage by applying an electrolyte solution together with a coupled electrical voltage. Several CT images are taken during this process while the first image is taken as the undamaged reference sample. The increasing volume of corrosion products in the specimens is then detected with image processing methods. The results can be statistically evaluated to depict e.g. the decreasing cross section of the rebar.

Projekt Description

After an initial 3D-CT of a concrete specimen three cycles of artificial damage followed by a 3D-CT image took place. This work has been carried out by our project partners at BAM.

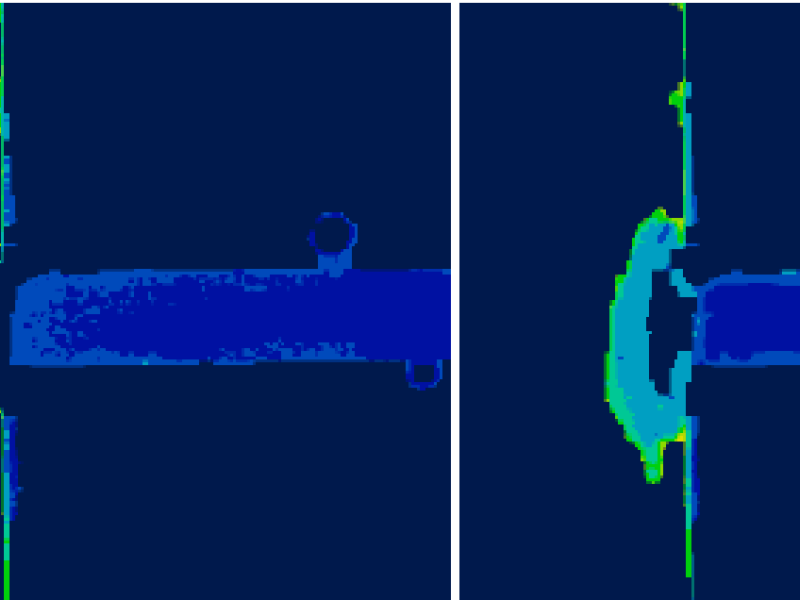

After that the CT images are registered to each other followed by a segmentation into rebar, crack (here an artificial gap), pores and mortar. Corrosion products where then detected by looking for typical grey values inside these segments resp. within a certain distance to the rebar together with region growing. The detected regions can be evaluated statistically for instance w.r.t. time and distance of the corrosion to the rebar.

Future Work

Up to now the corrosion detection relies heavily on the selection of the grey values which denote corrosion products. Moreover these grey values vary between the different segments. Therefore a new approach based on differences between the time steps should be tested.